Description

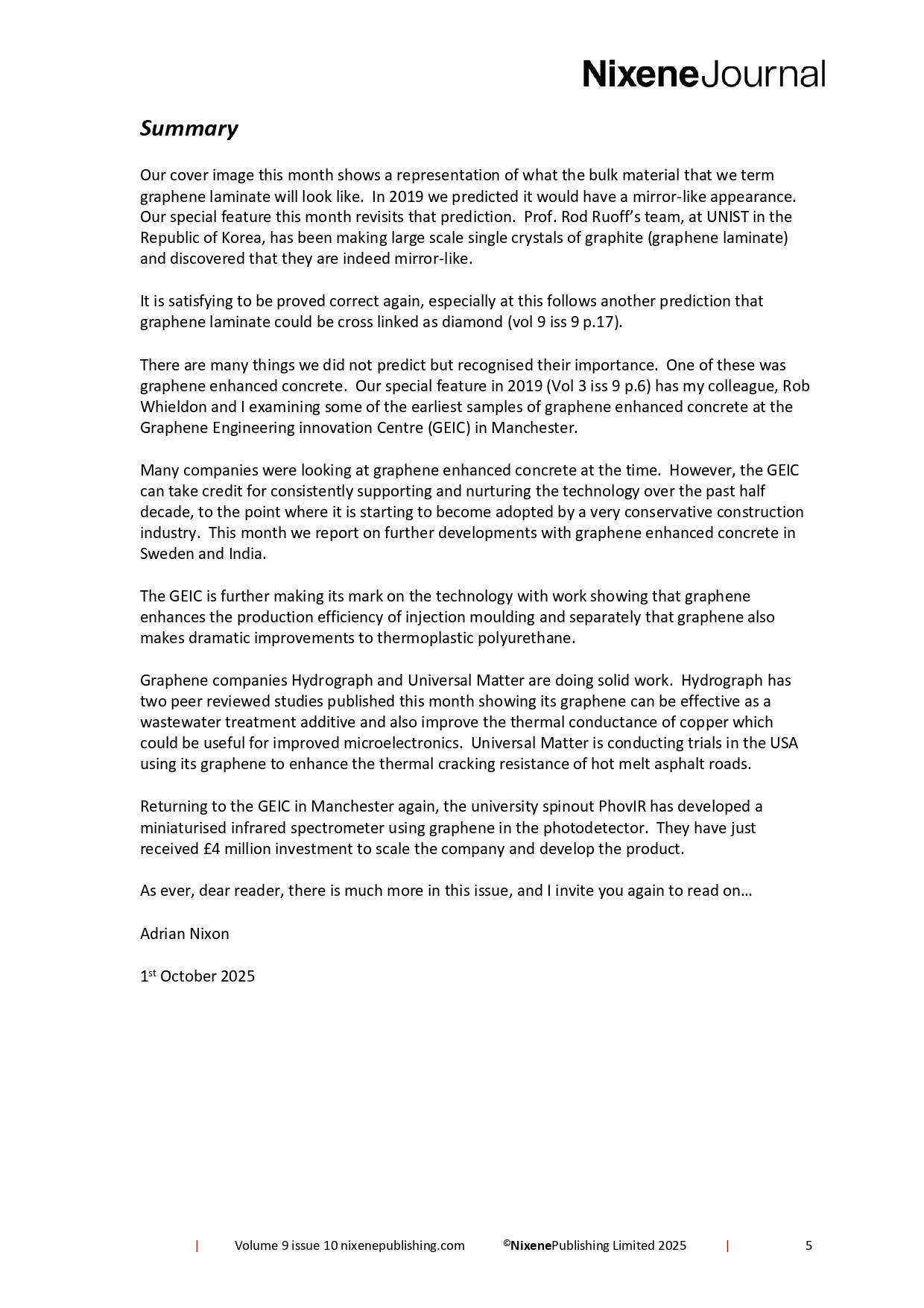

Our cover image this month shows a representation of what the bulk material that we term graphene laminate will look like. In 2019 we predicted it would have a mirror – like appearance. Our special feature this month revisits that prediction. Prof. Rod Ru off’s team, at UNIST in the Republic of Korea, has been making large scale single crystals of graphite (graphene laminate) and discovered that they are indeed mirror – like.

It is satisfying to be proved correct again, especially at this follows another pre diction that graphene laminate could be cross linked as diamond (vol 9 iss 9 p.17).

There are many things we did not predict but recognised their importance. One of these was graphene enhanced concrete. Our special feature in 2019 (Vol 3 iss 9 p.6) has my colleague, Rob Whieldon and I examining some of the earliest samples of graphene enhanced concrete at the Graphene Engineering innovation Centre (GEIC) in Manchester. Many companies were looking at graphene enhanced concrete at the time. However, the GE IC can take credit for consistently supporting and nurturing the technology over the past half decade, to the point where it is starting to become adopted by a very conservative construction industry. This month we report on further developments with graphene enhanced concrete in Sweden and India.

The GEIC is further making its mark on the technology with work showing that graphene enhances the production efficiency of injection moulding and separately that graphene also makes dramatic improvements to thermoplastic polyurethane.

Graphene companies Hydrograph and Universal Matter are doing solid work. Hydrograph has two peer reviewed studies published this month showing its graphene can be effective as a wastewater treatment additive and also improve the th ermal conductance of copper which could be useful for improved microelectronics. Universal Matter is conducting trials in the USA using its graphene to enhance the thermal cracking resistance of hot melt asphalt roads. Returning to the GEIC in Manchester again, the university spinout PhovIR has developed a miniaturised infrared spectrometer using graphene in the photodetector. They have just received £4 million investment to scale the company and develop the product.

As ever, dear reader, there is much more in this issue, and I invite you again to read on…

Adrian Nixon

1st October 2025